Ben's strengths at a glance

Plant-based protective power

Ben has laboratory-tested protective properties against external influences. It scores particularly well when you need high UV protection.

Thanks to its bio-based PLA film made from renewable raw materials (e.g. sugar cane or corn starch), we reduce the use of conventional plastic made from petroleum. This means that the packaging reduces additional CO2 emissions!

Matching shapes & sizes for your product

Stand-up pouches

6 sizes: XXS - XL

35 ml to 1.000 ml capacity

Functional all-rounder

Flat pouches

6 sizes: XXS - XL

15 ml to 950 ml capacity

Ideal for hanging

Printed rollstock

Individual dimensions

Suitable for your packaging machine

Perfect for Flow Packs, Pillow Packs & Sachets

Add-ons that optimally protect & present your product

Other advantages that Ben always brings

Ben's plant power is perfect for

Designs that immediately convince your product

Take it to the next level: with fully printed packaging

Common labels

Full paper look

Common labels

Full paper look

Our bio-based Ben impresses with its matt surface and fine paper structure. You can design it entirely according to your wishes - and adapt the design flexibly at any time thanks to small minimum order quantities of 500 pieces!

This could be your new organic packaging

For a first date with Ben: Our free sample kit

Get the packaging samples and get to know Ben better: Does your product fit into your desired size? Is the paper feel the way you want it? You have all the time in the world to test it. You're guaranteed to find the perfect packaging.

From nature, for nature

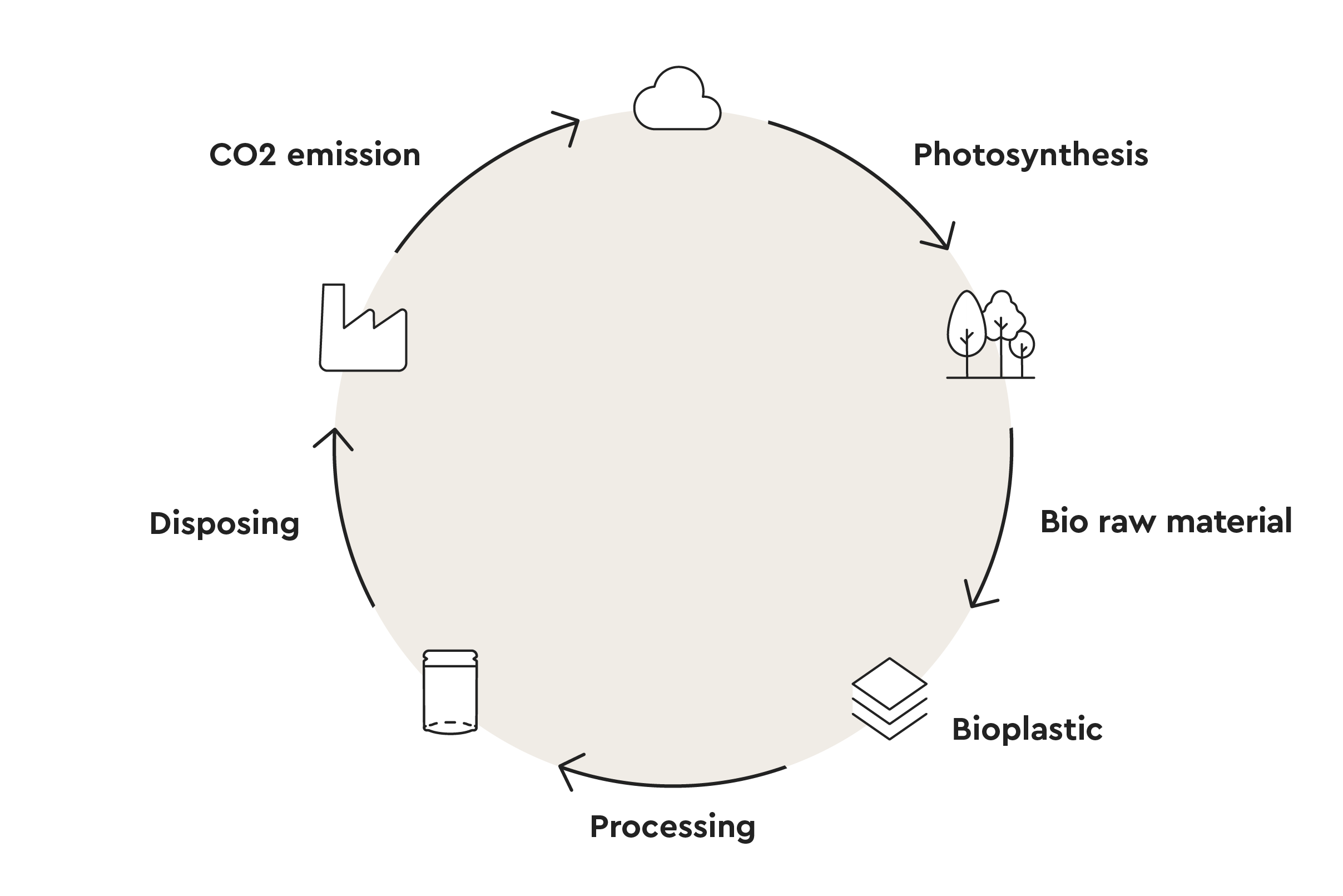

How Ben reduces additional CO2 emissions

Petroleum is used for the production of conventional plastic packaging. Millions of years old CO2 is bound in this petroleum. When the plastic is burnt, the CO2 contained in the petroleum is additionally released into the atmosphere.

Packaging made from bioplastics, on the other hand, is made from the starch of plants. These need CO2 for their growth, which they take from the atmosphere. When the bioplastics are burnt, only as much CO2 is released as was previously absorbed by the plant. This creates a kind of CO2 cycle. In this way, our organic packaging Ben helps to reduce additional CO2 emissions and protect our environment.

Potential to promote the organic circular economy

According to DIN standard 13432, Ben meets all the requirements for industrially compostable bag packaging. However, there are currently hardly any sorting and composting plants that are capable of doing this. BBen is therefore sorted out in the sorting plants and thermally recycled. As soon as more facilities meet the conditions for recycling compostable packaging, Ben can also be composted industrially.

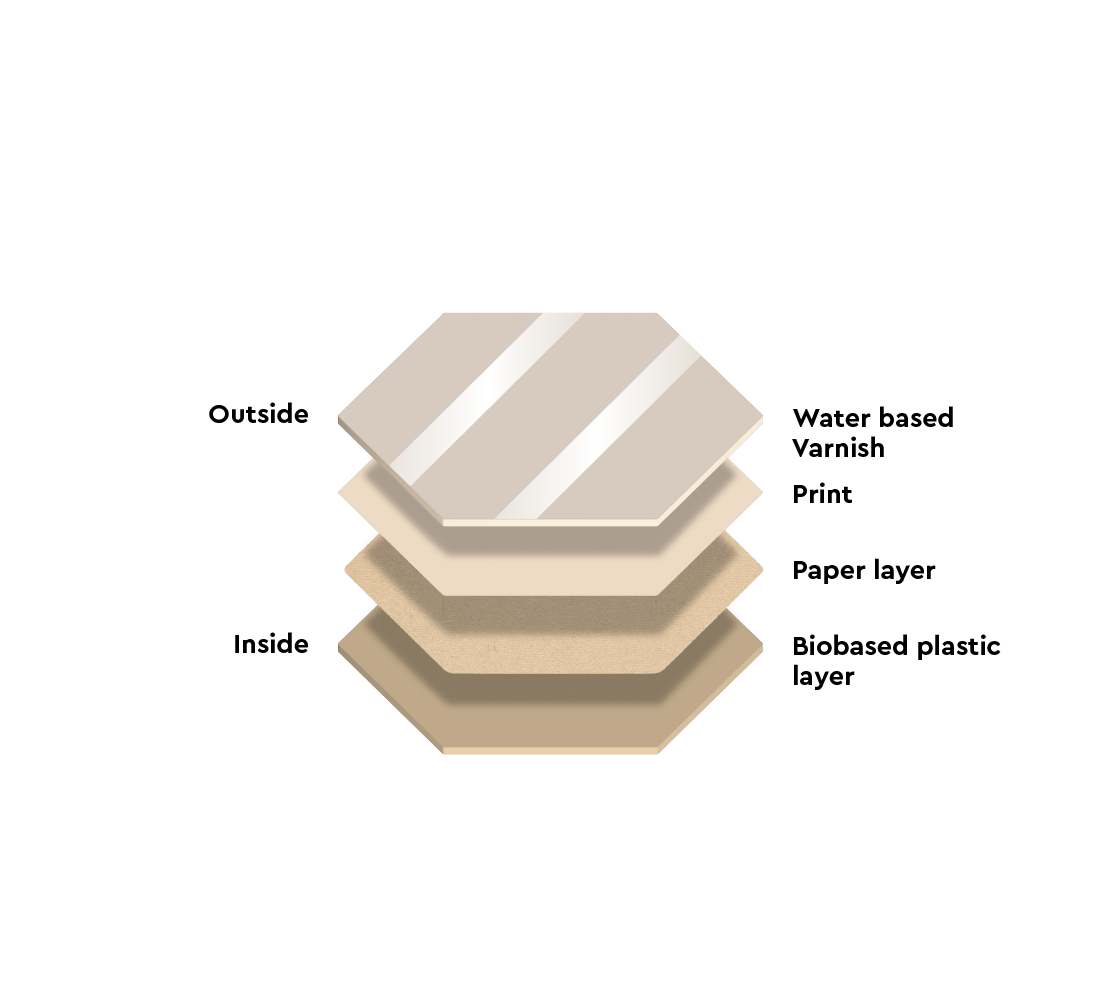

Well thought out down to the smallest paper fibre

The power of nature: That's what makes Ben so strong

Each layer of Ben's material has a different function and is therefore indispensable. Its bio-based PLA film made from renewable raw materials provides optimal protection against UV radiation.

Technical data of Ben

Data, Facts & Figures

WVTR

OTR

UV (A/B/C)

- FSC® certified paper

- Bio-based plastic (OK-biobased certification from TÜV Austria)

- Solvent free

- BPA-free

- Water-based varnish

You still have unanswered questions? We have the answers!

What design options do I have?

Our organic packaging can be printed over the entire surface from a quantity of 500 pieces. The surfaces can be designed in a matt kraft paper look so that your customers immediately notice the packaging on the product shelf!

How do I seal the organic packaging?

You can fill and seal our "Biobased Ben" by machine or by hand. It can also be sealed at the top edge.

Is organic packaging better for the environment?

Compared to conventional plastic packaging, biopackaging reduces additional CO2 emissions and promotes the biological circular economy.

Is our organic packaging really biodegradable or compostable?

Most bioplastics (including the PLA bioplastic used for Ben) are basically suitable for composting. If individual countries decide to enable their sorting and composting facilities to compost bioplastics, they can also be meaningfully recycled. In practice, however, this is still difficult, so that such plastics usually end up in the waste incineration plant.

What makes Ben sustainable?

Our Ben material is made of environmentally friendly paper certified by the Forest Stewardship Council® (FSC®) organisation for sustainable forestry. Our pouch packaging is resource-saving in production, consumes little CO2 in transport due to its low volume and weight and is produced exclusively in Europe. This keeps transport distances short and the CO2 footprint small.