"Made for Recycling" seal: Visible commitment without effort

What does the seal communicate?

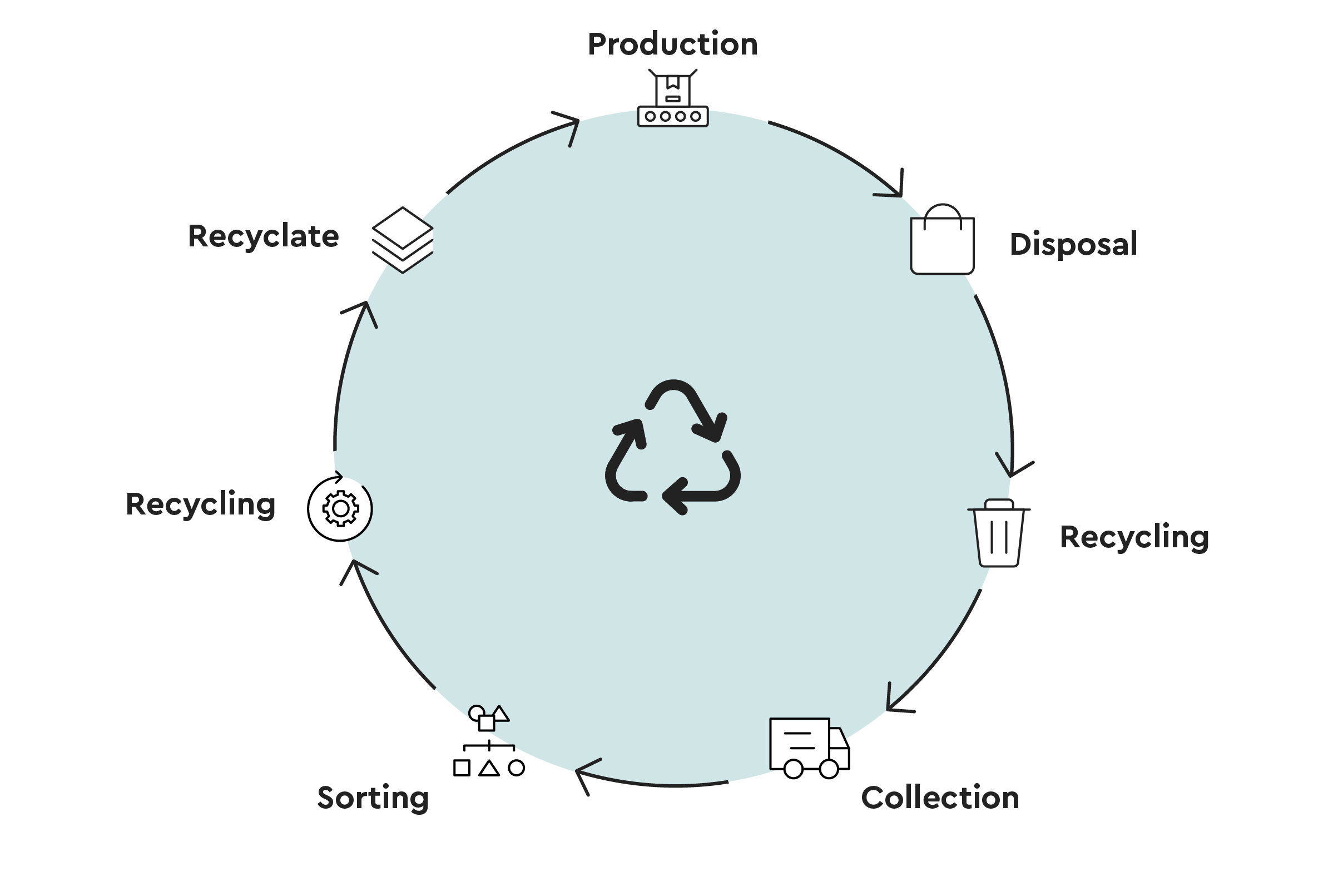

Promotion of a circular economy

Why is it so important that packaging is designed to be recyclable? Because it is an essential component of a functioning circular economy and contributes to it. This is based on the principles of reducing waste and pollution by recycling raw materials and plastics. Designing packaging that is recyclable not only in theory but also in practice is a challenge for many companies. That is why we have brought the environmental expert Interzero on board.

Who stands behind the seal?

Interzero tests the recyclability of packaging using an independent, scientific assessment method: development in cooperation with the bifa Environmental Institute and certified by the Fraunhofer Institute for Process Engineering and Packaging.

The evaluation criteria include the recyclability of the materials used, their sortability and the disposal options of the packaging. If a packaging achieves more than 18 out of a total of 20 possible points according to this method, it may bear the "Made for Recycling" seal. Just like our two materials "Toni" and "Martha".

Why is our packaging so easy to recycle?

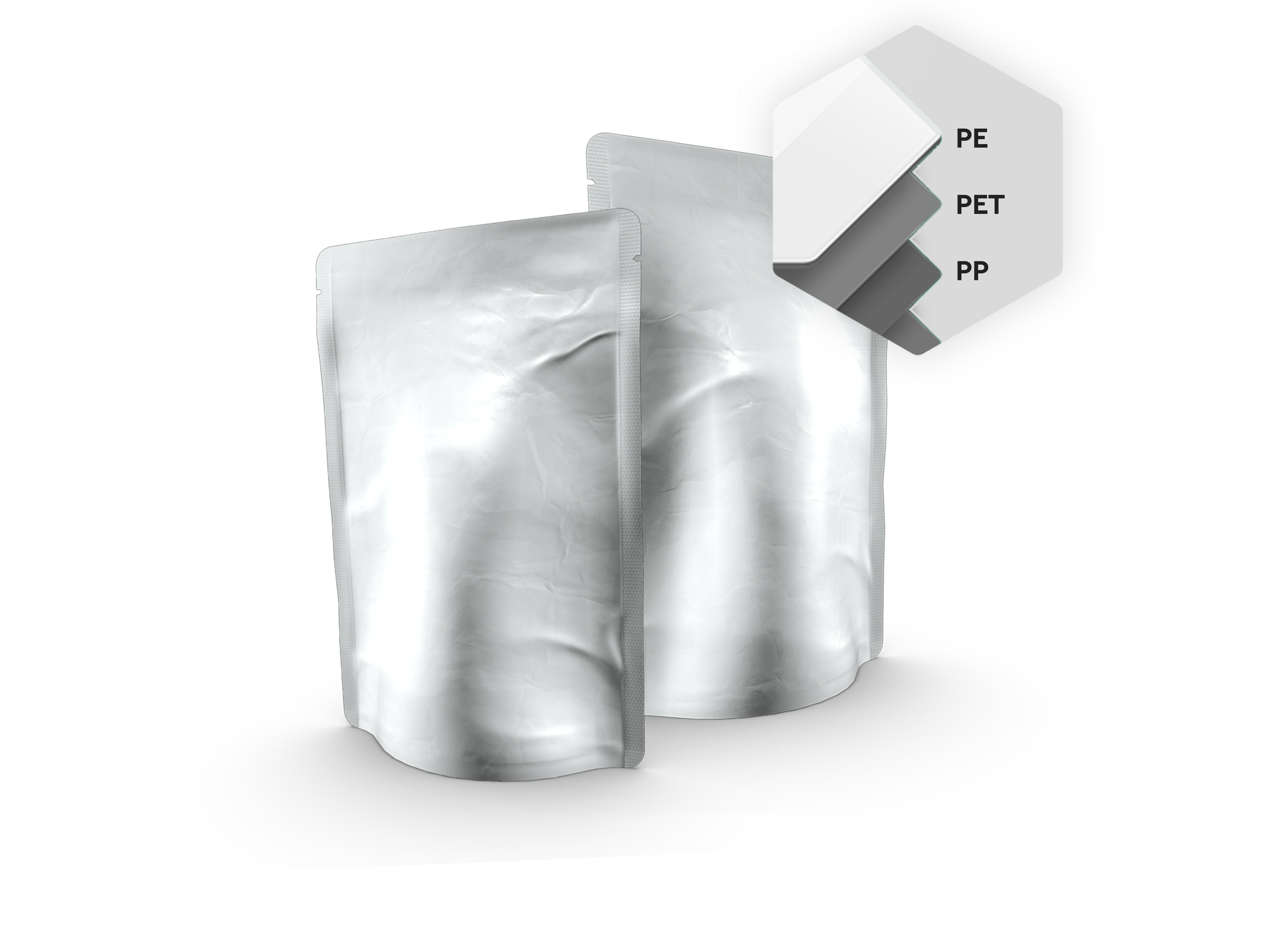

Non-recyclable multi plastic

Types of plastic that consist of different material layers (e.g. PE/PET/PP) can only be recycled with difficulty or not at all. The layers are so firmly bonded together that recycling plants can no longer separate them. Ergo: they end up in the waste incinerator.

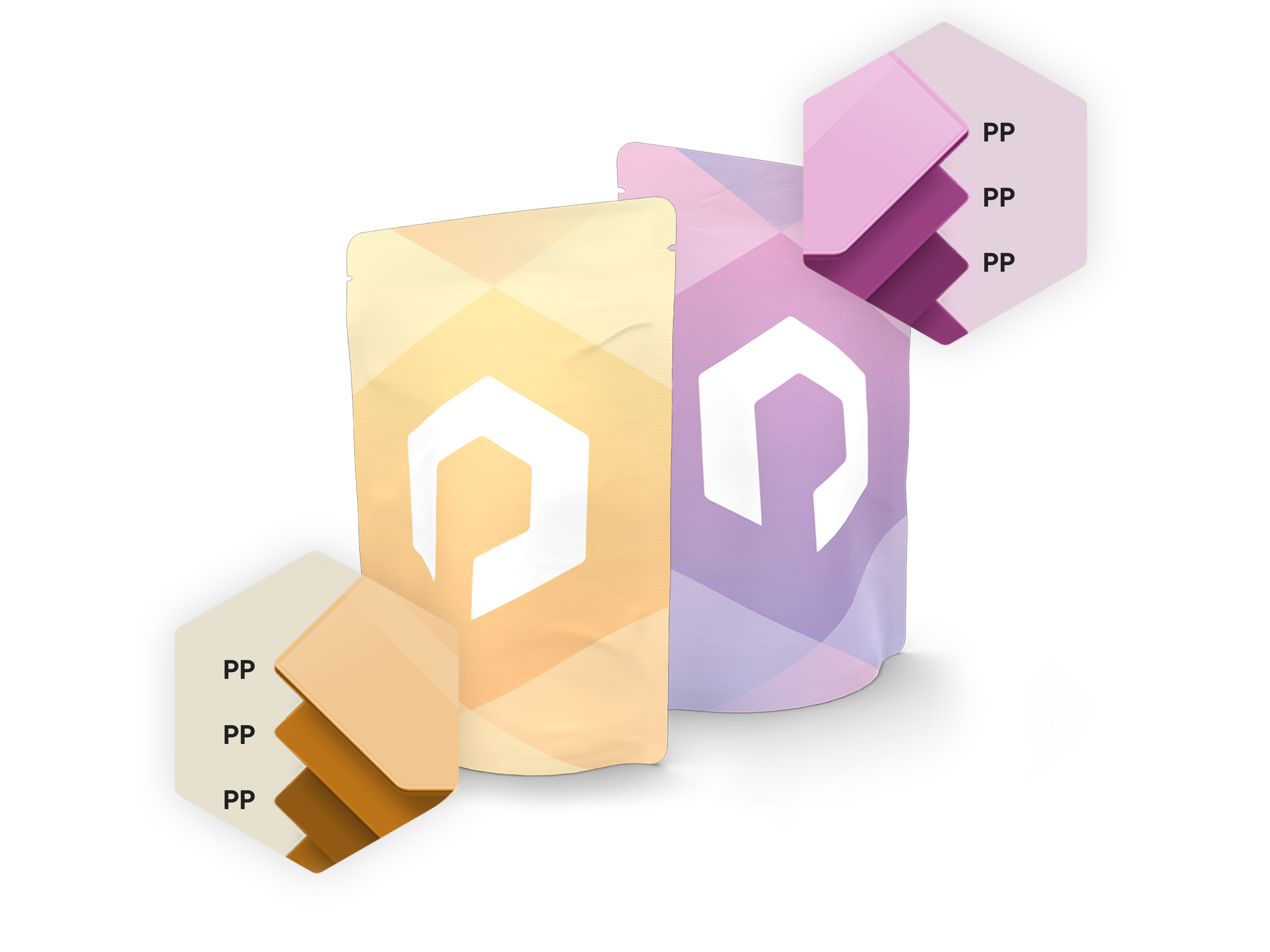

Recyclable mono-plastic

In order to optimally protect your product, our plastic packaging is also made up of several layers. The difference: These layers are all made of one material (PP/PP/PP) and therefore do not have to be separated in the sorting plant. This makes it possible to recycle one type of material!

This is how you benefit from the "Made for Recycling" seal

According to a study by KPMG and IFH Cologne, almost 80% of German residents attach great importance to environmentally friendly packaging. With the "Made for Recycling" seal from Interzero you demonstrably and verifiably underline your commitment to conserving our resources. Give your customers the assurance that they have made an environmentally friendly choice!

In 3 steps to the seal

Here are questions & answers

What happens to recycled packaging?

Recycling produces new raw materials (so-called recyclate) that can be used for new products. Of course, it is not possible to simply turn every old plastic bag into a new one. This is especially tricky with food packaging. Because we have to make sure that no dangerous chemicals from the recycled material get into our nourishment. To rule this out, a closed cycle must be ensured. Unfortunately, this has only been done very rarely so far, for example in the PET deposit system.

But even if the recyclate is used for other products than the original product (for example for a park bench), this kind of recycling is of course much better than incineration and complete new production based on new resources!

How can I tell if a package is recyclable?

Since recyclable packaging can hardly or not at all be distinguished from non-recyclable packaging, tested, independent and transparent seals such as the "Made for Recycling" seal provide the greatest security. But also material specifications on the packaging show you whether a packaging is made of only one or several types of plastic.

Some packaging also comes with a disposal notice: For example, a note on disposal in residual waste clearly shows that the packaging is not recyclable and will be incinerated with other residual waste.

Caution: The quality of recycling systems and the recyclability of materials vary from region to region and country to country. Packaging that is recyclable in one country is not necessarily recyclable in another.

How do I dispose of packaging with the "Made for Recycling" label?

Packaging with the "Made for Recycling" seal is recyclable and therefore belongs in the yellow bag. Incorrectly disposed materials not only interfere with the subsequent sorting process and have to be sorted out, sometimes laboriously, by hand or with special mechanical processes such as sieves or magnets - unfortunately, most of them are then incinerated.